I-24H I-hotline yensizakalo

021-58386189

Izixazululayo zokwenza amaqanda

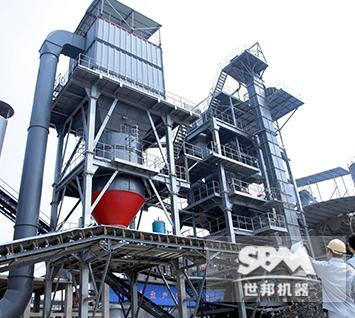

Ngenxa yinkingaIzindlela Zokulinganisela Ukuthuthukiswa Kwezinkolobisi Zehlathi E-Hunan. Ngesikhathi se-2012, ukukhuliswa kwesihlabathi somhlaba sangempela kwakugqashwe njalo. Kanti, ukukhiqizwa kwesihlabathi sesandla esenziwe ngemishini yendabuko kwakunezinkinga njengokulinganisa okubi, i-modulus enkulu yamancinci, isimenga esimnyama esinezindinganiso eziphansi nokuthuthukiswa kwamanzi, njll., okuholele ekuhlaselweni. Ngesilinganiso salokhu, uLONGCHENG Inc., umkhiqizi odume kakhulu wamalasha okwakha, wathengisa ku-SBM i-VU Aggregate Optimization System, isiqondiso esiphezulu emhlabeni sesihlabathi somhlaba oshisayo, futhi sayisebenzisa ngasekupheleni kwe-2015, kanye nokuqeda ngokuphelele izinkinga ezazikhona emkhankasweni wokwenza isihlabathi ngamanzi njenge-modulus enkulu yamancinci, ukuncipha kwenzuzo nokukhubazeka kwe-se-.

I-Hunan yilona linye lamaphrovinsi anezinsimbi zemvelo eziningi ze-sandstone, lapho izinsimbi zemvelo eziphezulu zabelwe khona endaweni ye-Xiang River ne-Dongting Lake. Kodwa, eminyakeni embalwa edlule, ukuphelelwa yimikhuba yemvelo yokukhiqiza i-sand ehlukaniswe nezinkinga eziningi emkhakheni we-sand yokwakha yenze ukuba ukukhishwa okungeyona yomthetho kwenzeke njalo, okwenza kube nobungozi emkhawulweni wesimbi sesandstone e-Hunan futhi kwandisa izindleko zokukhishwa. Ngemva kokukhishwa kwe- Izindlela Zokulinganisela Ukuthuthukiswa Kwezinkolobisi Zehlathi E-Hunan. ngo-2012, ukukhishwa kwesand yemvelo kuye kwagqashulwa njalo.

Ngaphansi kwesimo lapho isihlahla sangempela singabukeka singenelela futhi siyabiza kakhulu, isihlahla esenziwe yi-mashini, njengomthamo, sikhula ngokushesha, sifakazela umkhondo wesiqephu sesihlahla sangempela. Kuze kube manje, i-Hunan ikhiphile imithetho eminingi ukuze ikhulise imisebenzi yensimbi yemashini. Kwezinye izindawo, imibhede yempahla, izimpahla zokwakha nezitsha zisetshenziswa ukuze kwenziwe isihlahla ukuze kuthuthukiswe insizakalo yokubuyisela ngakho, umkhiqizo wesihlahla esenziwe yi-mashini ubonakala njengomkhakha wendabuko njengawokuqala.

Ukwenza i-sand ngamashumi-kanye ngendlela yendabuko kwasetshenziswa isikhungo sokulungisa i-sand esinomoya, okulawula inani le-stone powder ngokusebenzisa ikhono lokugqoka amanzi. Ekusebenziseni i-sand eyenziwe ngamashini, ingxenye yemifino encane engaphansi kuka-0.6mm yayiyosuswa ndawonye nemifino, izinto ezingcolile kanye ne-stone powder engaphansi kuka-0.075mm. Lokhu kwakhohlise ukwahlukaniswa okuhle, i-fine modulus enkulu kanye neconcret ezinamandla amancane. Ngaleso sikhathi, futhi kuncishisa umkhiqizo, kukhipha izinsimbi futhi kubangela ukungcola kwamanzi, okukhubaza ukukhiqizwa okuhlanzekile.

Ngenxa yokuthi kukhona izidingo ezinkulu zamaqanda okwakhiwa yimishini aphezulu eHunan kanye nobukhulu bezinkinga ezaziqalile ngohlobo lokwakha amaqanda olukhulu, izimboni ezakha amaqanda ziqale ukufuna ikhono elisha lokulungisa lelo. Ngakho-ke, lesi sikhathi iLONGCHENG.Inc. yakhetha uhlelo lwe-VU Aggregate Optimization System lukaSBM olusebenzisa ikhono lokwakha amaqanda olukhulu olukhulu. Luvimbela izinkinga ezisenziweni lokwenza amaqanda olukhulu futhi lungakwazi ukwenza amaqanda okwakhiwa yimishini aphezulu ukulungisa amaqanda emvelo. Ngakho-ke, uhlelo lwe-VU lwatholakala luhlonishwa kakhulu yizimboni ezihlanganyela nabo.

Izinto ezisemthethweni: itshe elihlombe (i-tailing evela ezifakazini zemathiriyeli yetiye, amakhethini amatshe aphansi kwemali)

Ukhulu lwokuhlwanyela: 5-15mm

Ukuhlanza kwamanzi: <2%

Ukuhlanza kwe-silt: <1%

Ukusetshenziswa kwemveliso: Isanti ephezulu yempahla isetshenziswa ekulungiseleleni ikhonkrithi kanye ne-mortar ehlanganisiwe; umthwalo wamatye ophezulu wokuhlanganisa i-fly ash.

I-modulus ephansi ye-sand eyakhiwe yimishini: 2.7±0.1

Ukuqina komthwalo wamatye kufanelekela isiqondiso sesibili se-fly ash.

I-Granite

Umthwalo wamatye ophezulu wempahla

Isanti ephezulu yempahla eyenzelwe ukulungiselela ikhonkrithi

Isihloko: Isanti esiphezulu esisetshenziswa ekulungiseni i-mortar ehlanganiswe ngomoya.

Ukuze kuphumelele ukucelwa okukhulu kwe-sandu ephezulu nokuthuthukisa imisebenzi ye-concret ne-mortar, i-SBM yachitha iminyaka engu-5 yokuqeqeshwa kwe-VU system endaweni yokuhlolwa kokuhlolwa kwe-aggregate ekhethekile ngaphezu kweminyaka engu-30 yokuqeqeshwa kule ndaba.

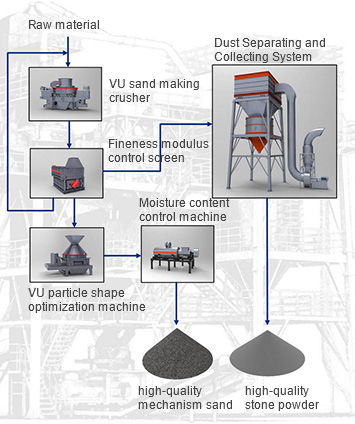

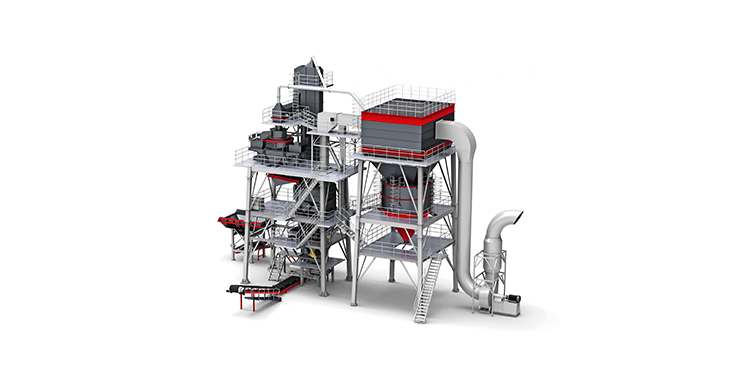

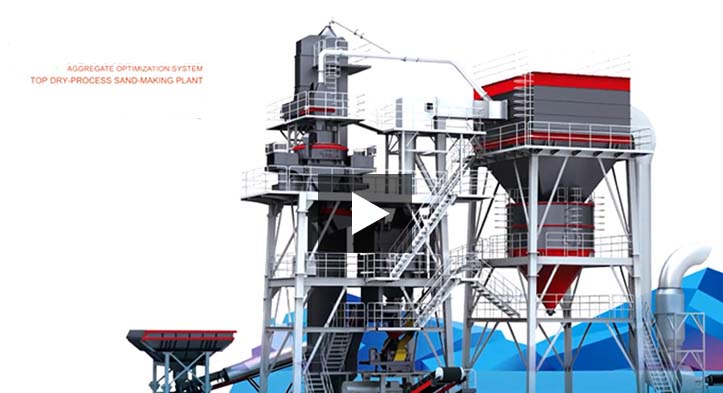

Isiqondiso se-VU Aggregate Optimization System sisisetshenziswa ukwenza isandu yemishini ephezulu, eyenqaba izinkinga ezisesimweni se-sand-making kuhlanganise nokuchotshelwa, ukuqoshwa nokuhlukaniswa.

Ngenhlobonhlelo elilandelayo, i-VU Aggregate Optimization System yayiphinde ihlangabezane ngokuphelele nezindinganiso zokukhiqiza i-sand eyenziwe yi-machine yomthengi.

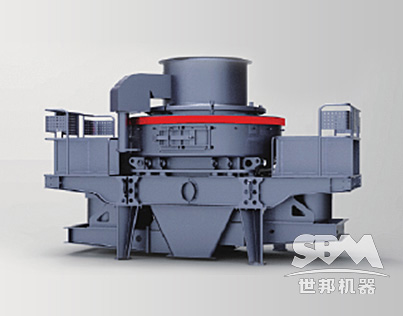

Uhlobo olusha lwe-VU Sand Making Machine kuqala luqonde izindlela zokushintsha ezifaka i-high-frequency "i-stone hitting stone" kanye ne-"material cloud". Uma kuqhathaniswa ne-VSI Sand Making Machine, i-VU system iphinde yandisa ukukhiqizwa kwe-sand.

-----Ukusebenza Okuphezulu

Ukuhlanganiswa kokucubungula, ukwahlula nokwahlukanisa iphunga, isikrini singenza ukwahlulwa kwempahla namaqabunga ngesikhathi esisodwa ngenxa yokuvimba kwayo okugcwele, ukususa iphunga ngesivinini esibi nangekuhlukaniswa okuhle.

Ukhulu lokukhanya nomkhondo we-flow ungafinyelela ukuguqulwa okuqhubekayo nokucholisayo okungavamile ngaphandle kokushintsha i-mesh yesikrini nezinye izingxenye. Ukuqina kwezinto ezimboza kunga lawulwa phakathi kwe-2.5-3.2, inani lephunga liphakathi kwe-3-15%.

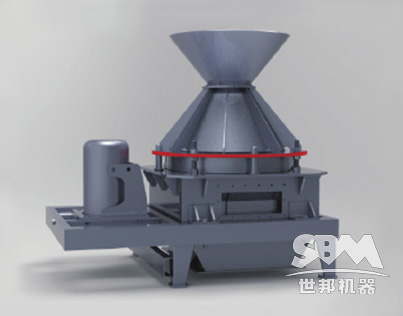

-----Ukwenza okulungile kwezimo zezicucu

Ngenxa yokulingisa isimiso sokwenza umhlabathi olukhulu, imeyishi ithatha imikhondo ephambili ye-global ye-"ukucicisha i-energy encane kanye nokwembasa" kanye "nokuzikhulula ngendlela yokugoba", okuyisizathu esiyenza ukuba kube khona ukususwa kwamakona endaweni yokuqala kwemveliso kanye nokukhula kwamazinga okukhulu okukhulu kumhlabathi oqine ngama-0.6mm, i-voidage iyancipha ngama-1-2%, isikhathi sokudluliselwa kwe-5%.

Itheknoloji entsha yokulinganisa, eyinhloso, iyanciphise ukusetshenziswa kwamandla futhi ithathe isikhathi eside kunoma yiliphi isikhathi somshini owenziwa ngenhla (Ngaphansi kwesimo esifanayo, isikhathi sokuqhubeka siyizikhathi ezingaphezu kweshumi ze-impact crushers).

Ukusetshenziswa kwesixhumi sokuqoqa uthuli olunamandla angamahhala kanye nenqubo yokusebenza evulekile kwenza kube khona uthuli nolwazi olungcono, oluhambisana ngokuphelele nezindinganiso zezwe zokwakha “okumhlophe”.

Ukuklanywa kokulandelela kwawo wonke amasimu kanye nokukhishwa kwempahla yempahla efinyelelwe ngempahla kwenza kube lula ukugcina izinto ezincane nempahla zokuthutha ngokucindezela inkinobho. Kuyanciphisa kakhulu umsebenzi wabantu kanye nezindleko zokusebenza.

Imisebenzi yokulawula nokulandelela imishini yonke ihlanganiswe esimisweni sokugcina esikhulu, okwenza inqubo yokusebenza ibe lula kakhulu futhi kuqinisekise ukukhiqizwa okuphephile, okuqhubekayo nokuqinile.

Ukufakwa nokugcinwa kwemiphumela yokusebenza emihle kunikezwa. Futhi ukukhululeka kwezimpahla kuqinile. Lesi simiso singenza ukukhiqizwa kube ngaphezulu futhi sigcine izinga eliphelele lokusebenza kakhulu.

Isinyathelo sokuqala:

Ukucwiliswa: Itshe elikhulu liqokomana ngaphakathi kumasinyathelo e-VU Sand Making Machine ukuze licwilwe. Izinto ezifana ne-flat-elongated kanye namacala esanti lapha ahlulwa ukuze kutholakale ubukhulu besanti obudingayo.

Isinyathelo sesibili:

Ukwahlula nokuhlela: Itshe elikhulu elichwilwe liphonswa ngokulinganayo ngaphakathi kwe-VU FM Control Screen nge-feeder. Ukwahlula isanti eliqeqeshwe yi-mashine kuyikontrolwa ngokuqondile ubukhulu besanti eliqeqeshwe yi-mashine. Khona-ke izinto ezingafaneleki zithunyelwa emuva ezincwilisini ukuze zicwilwe futhi.

Isihloko sesithathu:

Ukwenza kahle umkhawulo wemicu: Impahla yomhlabathi yesandla esenziwe ngemishini eyayeqeshwe yi-FM Control Screen ingena emashinini wokwenza kahle umkhawulo wemicu. Izindlela zokugcina zomhlabathi zizosuswa lapha.

Isihloko sesine:

Ukudlulisa kanye nokuthutha: Impahla yomhlabathi eyenziwe ngemishini eyenziwe kabusha ingena ekusebenziseni i-humidifying blender ukuze ibe nomswakama. Ukugeleza kwamanzi kumhlabathi okugciniwe kulawulwa ukuze kuqinisekiswe nakakhulu izinga lokuthuthwa komhlabathi.

Isihloko sesihlanu:

Ukuthutha, ukugcina kanye nokugcwalisa: Inqwaba yamatye ayikudingiwe iqoqwa yi-pulse dust collector bese ithunyelwa engxenyeni yokugqoka

Ngemva kokuthola ukuqonda okucacile ngezimo ezahlukene zomthengi, siye sakhiqiza isikhombisi esifanele emva kokuxoxisana ngezimo ezithile, ukukhipha izindinganiso nezifiso. Lokhu kuqinisekisa ilayini yokukhiqiza efaneleke kakhulu, enomthelela oqeqeshiwe futhi ephumeza izinzuzo eziphezulu ezihlelwe ngokwezifiso zomthengi.

I-SBM yathuthukisa i-VU Aggregate Optimization System ephelele ngokuzenzekelayo eyenzelwe ukufana nezidingo zokulinganisa/ukulinganisa i-fineness modulus kanye ne-powde

I-SBM inenqwaba yamaqembu wokunakekelwa ngemva kokuthengiswa anezakhono kanye nobuchwepheshe. Bonke amalungu aqinisekile futhi anentshisekelo. Kuze kube manje, amakhulu ezinkulumo zomsebenzi wochwepheshe zikwamukele insizakalo yokufakwa nokuqeqeshwa. Ngesikhathi esifanayo, i-SBM izosiza abathengi ukuba baqeqeshe abasebenzi babo abasebenza kuze kube yilapho bengakwazi ukusebenzisa imigqa yokukhiqiza ngokuzimela.

Ukuze abathengi baqonde ukulungiswa nokubuyekezwa kwebhayisikili, i-SBM inikeza abathengi incwadi yemibhalo yebhayisikili ebonisa ukuhlaziywa okucacile kwamakhasi kanye nokukhumbuza yonke ingxenye. Lokhu akusizi nje kuphela abathengi ukuba baqonde izakhi zebhayisikili kodwa futhi kwenzeke ukuba abathengi bazithuthukise.

Iyonke imishini yokuhlolwa kwe-VU Aggregate Optimization System ehlinzekwa yi-SBM iqinile ngokwakhiwa kwayo futhi iyindlela elungiselelwe ngayo. Le mishini iyakwazi ukwandisa ukusebenza futhi inciphise izindleko zokusebenza. Yonke inqubo yokukhiqiza ayinakho umdaka futhi ama-stone powder angaphezulu aqhubekisela kabusha. Ama-stone nama-sand akhiqizwe ane-shape ephelele yeqolo. Ukulinganisa kwe-sand kuqondene. Ngakho ukulungiselela ikhonkrithi endlini yokuxuba kuhle kakhulu futhi kuncishisa ukusetshenziswa kwecementi. Ngakho izindleko zokukhiqiza zinciphisiwe.

Ukwahlula:Kwesixazululo se-dry-type sand-making system, ngemva kwenjini yokwahlula ama-powder, ama-particle emhlabeni esihlabathini esenziwe ngesandla angasuswa futhi i-sand ingafinyelela imigomo yokwakha. Ngaphezu kwalokho, inani le-stone powder kwi-artificial sand lingalawulwa ngesixazululo sokuhlukanisa ama-powder ngaphansi kwamalungiselelo ezwe ukuze ukwakheka kokunamathisela nokuhlanganiswa kwama-concrete kukhuliseke. Nge-production ye-wet-type, ekuhambeni kweprosesa yokugeza i-sand, i-washing sand izo-

Ixabiso: Indleko yokukhiqiza umkhondo wokwenza isanti yomhlobo oqinelekileyo (dry-type) iphansi kakhulu ngoba isebenzisa imeyishi yokwahlula amafutha nothuli (powder separating machine) enempumelelo ephezulu ukuze iwahlule isanti nothuli futhi ayidingi amanzi amaningi ukugeza.

Isimo Sengqondo: Ayinawo umkhawulo ngamanzi nangezimo zokusebenza, isimiso sokwenza isanti yomhlobo oqinelekileyo singakwazi ukwenza isanti ezindaweni ezingenawo amanzi amaningi. Kodwa kumkhondo wokwenza isanti yomhlobo oqhumulayo (wet-type), ukwenza isanti kufanele kwenziwe ezindaweni ezinezinsiza ezanzi zezamanzi. Futhi ukukhiqiza akunakwenzeka ngeentwasahlobo ezindaweni ezineziphakamiso ezinkulu.

Ukukhuseleka kwesimo sezulu: Amanzi akuyona into edingekayo ekuhambeni kokwenza okomile. Iphutha lesihlabathi ekuveliseni lingasetshenziswa kahle. Ngakho, kuze kube manje, amanzi nemithombo yeminerali isetshenziswa kancane. Ngaphezu kwalokho, ayikho izinto ezigqithisiweyo zezinto zokwakha nezinto zokwakha. Kuyenza umsebenzi okhuselekile kunenkqubo yokwenza amabala amanzi.