Meniyo

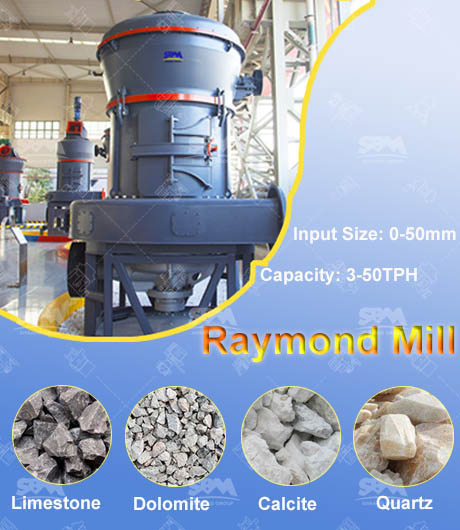

Raymond Mill na'urar nika ce, mai dacewa don shirya nau'ikan foda na ma'adinai da foda gawayi.

Kayan aiki:Barite, calcite, potash feldspar, talc, marble,<br>limestone, dolomite, fluorspar, lime, activated clay, activated carbon, bentonite,<br>kaolin, siminti, phosphate rock, gypsum, da sauransu.

Amfani:Fannin karfe, injiniyan sinadarai, kayan gini,<br>hako ma'adinai, magani, kayan kwalliya da sauran fannonin

➤Matsayin Moh ƙasa da Matsayi 7

➤Ruwan ƙasa da 8%

➤Baƙin karfe da ba a ƙone ba da duk da haka ba a pataku ba

➤Girman abinci yana tsakanin 40 zuwa 400 meshes

A shekarar 1906, C.V. Grueber ya kafa wani masana'anta a kudu maso yammacin Berlin. Tare da amfani da patent din da ya samu a Amurka, ya samar da na'urar Maxecon ta farko kuma ya yi amfani da ita a matsayin kayan nika gawayi don tashar wutar MOABIT. Ikon nika yana iya kaiwa 5TPH. A cikin 'yan shekarun da suka gabata, kusan raka'a 600 an sayar dasu kuma ana amfani da su a masana'antu daban-daban. A cikin wannan lokaci, BEWAG ta shirya don haɓaka wani mill gawayi tare da fitarwa mafi girma. Bayan E.C. Loesche ya karɓi ragamar kuma ya jagoranci C.V. Grueber Machinery Plant, ya yanke shawarar sayen Raymond Centrifugal Ring-roller Mill daga Amurka don samar da ƙarni na farko na tsarin Raymond Mill.

Amma, gwaje-gwaje sun tabbatar da cewa ƙayyadaddun ƙimar samfuran da Raymond Mills suka samar ba su gamsu ba. A kullum, ƙimar yawanci tana kusa da 400 meshes, tare da ƙaramin kayan da ke da ƙimar har zuwa 1000 meshes, wanda ba ya cika bukatun haɓaka inganci. Wannan nau'in Raymond mill ba ya dace da kayan gawayi da suke da laushi, ƙananan ƙurar ash da kyakkyawan halayen nika, saboda ƙarfin nika (ƙarfin centrifugal) na Raymond coal grinding mill yana iyakance gaskiya bisa diamita da saurin juyawa na rolling nika a lokacin. Duk da haka, gawayi na Jamus yana da halaye na ƙarfi da yawa ash, wanda ya buƙaci ƙarfin nika mafi girma. Don haka, Raymond mill na wannan tsari ba a yin shahara a Jamus kamar yadda ya yi wahalar cika buƙatun nika. Amma abin mamaki shine wannan nau'in Raymond mill yana dace da ingancin gawayin a Amurka, babu shakka cewa Raymond mill an yi amfani da shi sosai da kuma aikace-aikace a Amurka.

A cikin 1925, E.C.Loesche ya nuna halayen amfani da rashin fa'idodin farko na na'urar niƙa ƙone ƙwayoyin Raymond da ya yanke shawarar inganta tsarin na'urar Raymond. Ya haɓaka na'ura mai niƙa wacce tsarin niƙa ta ya sha bamban da na farkon, wanda aka kira ingantaccen Raymond mill.

Hanyar shakar iska na wannan tsarin ingantaccen Raymond mill yana da hanyoyi guda biyu: matsin lamba mai kyau da kuma matsin lamba mara kyau da aka fesa kai tsaye. An mallaki haƙƙin wannan irin na'urar Raymond cikin sauri daga Combustion Engineering (kamfani a Amurka).

Raymond mill da aka haɓaka har yanzu suna da matsaloli akan jigon shi har yanzu. Duk da cewa diamita na jigon ya ƙaru kaɗan, ba ta yi aiki sosai ba.

Nan gaba, Combustion Engineering ta haɓaka sabon jeri na Raymond mill a ƙasa, wanda aka kira VR mill.

Tsarin wannan Raymond mill yana da kama da na Loesche mill na yanzu a cikin fannoni da yawa. Duk da haka, ya sha bamban da Loesche mill akan jigon niƙa mai silinda da teburin niƙa tare da shimfidar murabba'i mai digiri 15. An tsara jigon niƙar tare da na'ura mai fitar da ita don bincike da kulawa. Hakanan yana dauke da na'ura mai kariya don hana haɗin ƙarfe tsakanin jigon niƙa da teburin niƙa. Bugu da ƙari, jigon niƙa na iya ɗagawa a gaba kafin na'urar ta fara wanda zai iya rage jujjuyawar jawo.

Ana amfani da Raymond mills akai-akai don yin ƙone ƙwayoyin pulverized a cikin Ƙungiyar Amurka. Ingancin samfurin da aka gama yana bambanta tsakanin 250-325 mai ƙarfi (inganci da fitarwa za a iya daidaita su yayin aiki).

Tun lokacin da aka mallaki haƙƙin Raymond Mill, ya wuce fiye da shekaru cinquanta. Tare da shekaru na ci gaba da haɓakawa, ana haɓaka nau'ikan daban-daban da samfuran Raymond mill tare da kyakkyawar aiki, ƙarfin jujjuyawa mai ƙarfi da aikin da ke da inganci.

SBM ta ƙaddamar da jerin inganta na Raymond Mills guda uku, MB5X Pendulum Roller Mill, MTW European Grinding Mill da MTM Medium-speed Grinding Mill. Dangane da na'urar niƙa ta farko ta Raymond, waɗannan nau'ikan guda uku na na'urorin niƙa sun fi tsada mai kyau da kare muhalli, suna da tsarin kula da atomatik mai fasaha, kuma suna iya taimaka wa masu amfani su tafi kan hanyar ci gaba mai kyau da manyan girma.

Daga binciken tarin bayanan gwaji na bayanan gwaji na shafin fiye da shekaru talatin, SBM, wani mai ƙera na'urar niƙa daga China, ya gudanar da bincike da haɓaka na na'urar niƙa ta biyar - MB5X grinding mill. Duk kayan mineral masu laushi da marasa fashewa waɗanda ke da ƙarfi na Moh ƙasa da Mataki 7 da kuma ƙarin ruwa ƙasa da 6% za a iya niƙa ta wannan na'urar niƙa.

MTW European Grinding Mill an tsara shi cikin sabuwar hanya ta hanyar zurfin bincike kan grinding mills da ƙwarewar ci gaba. Yana ɗaukar sabuwar fasahar ɗan gwangwani ta Turai da ra'ayi, kuma yana haɗa shawarwarin abokan ciniki 9158 kan grinding mills. Wannan grinding mill yana cika bukatun samarwa na abokan ciniki akan 200-33μm (80-425Mesh) ƙananan ɗan gwanin shanu.

Kamar yadda muka sani, Raymond mill ana yawan amfani da shi don sarrafa ores mara ƙarfe (haɗa da kwal) kuma yawancin kayayyakin da aka ƙera suna ɗauke da wani adadin danshi mai ɗiyan. A yau, mushy "shin raymond mill zai iya sarrafa kaolin" da "shin raymond mill zai iya sarrafa celatom" suna bayyana a duk faɗin intanet. Raymond mill yana yin amfani da shi a hankali cikin fannoni daban-daban.

A masana'antar yin takarda, celatom, bayan sarrafawa ta hanyar Raymond mill, yawanci ana amfani da shi a matsayin cike lokacin yin takardar sigari, takardar tacewa, takardar kariya, takardar shiryawa, takardar ado, wanda zai iya rage raw material da haɓaka halayen takarda.

A masana'antar karfe, Raymond mill ana iya gani a fannonin kamar karfafa ƙarfe, haɗa na'ura, sarrafa kayan jiki na karfe, amfani da sharar karfe, nau'in halitta da yashi da dutse, kayan da ba su da ɗan karfi da mai maiƙa, da sauransu.

A masana'antar kayan gini, muhimman sassa na Raymond mill suna yi daga ƙarfe mai inganci, kuma sassan da suke jurewa gaji suna yi daga kayan da suke da ƙarfi mai inganci, wanda ke tabbatar da ingantaccen aiki a cikin sake amfani da shara daga ginin.

A masana'antar sinadarai, Raymond mill ana amfani da shi don sarrafa gipsum, talcum, titanium dioxide, yashin kashi, yashin ruwa, carbon black, gawayi, nau'ikan roba, alum da sauran sinadarai.

Bayan haka, Raymond mill yana dacewa da kananan da matsakaitan masana'antu. Raymond mill yana inganta sarrafa kayan da suke 5 ko ƙasa a kan ma'aunin wahala na Mohs. Akwai ƙananan iyakoki, amma mafi ma'ana sune kayan laushi zuwa matsakaici.

Raymond mil yana kunshe da muhimman na'urori kamar na'urar grind, classifier, reducer, star rack da tarin gugar grind da sauran sassan da ba su lalace.

Na'urar grind: na'ura tare da gugar grind na kwararru da zobe grind. Ayyukan grind yawanci ana kammala su a cikin na'urar grind; gugar da aka niƙa tana tafi tare da iska mai tantancewa kuma ana tantance ta da kyau ta hanyar classifier.

Reducer: tsarin isar da iko wanda ke amfani da mai canza sauri na cogwheels don rage yawan juyawar motar kuma don haka samun torque mafi girma.

Star rack: idan mil din na aiki, na'urar tana motsawa ta hanyar main shaft sannan ta realize juya gugar grind da zobe grind.

Tarin gugar grind: tarin na'ura wanda aka dauke a kan star rack, kuma shine babban na'ura na injin Raymond da kuma sashin da yafi samun gazawa kuma yana bukatar hankali don cika mai a kan lokaci.

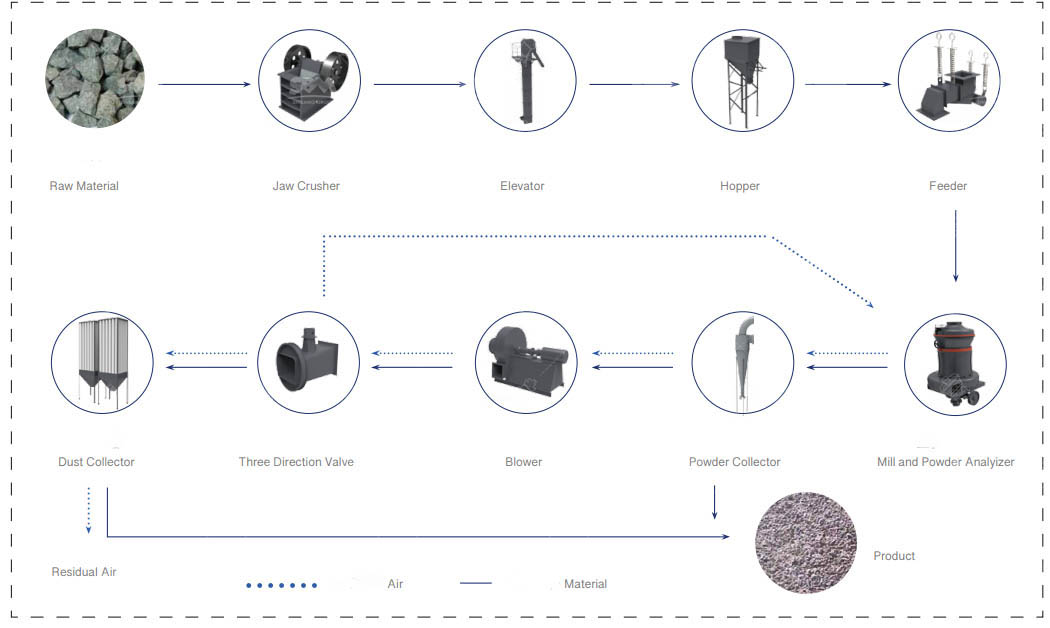

bayan jaw crushers sun karya manyan kayan da suke da nauyi zuwa ƙananan, elevator suna aiki don aika kayan zuwa hopper. Sa'an nan, ta hanyar na'urar girgije ta lantarki, an tura kayan da aka karya a cikin daidaito da adadi zuwa dakin grind na Raymond Mill.

Bayan an yi grinding, kayan suna busawa ta hanyar iska zuwa wajen tarin guga don tantancewa. A karkashin aikin impeller na mai tantance guga, kayan da ba su kai ga kauri za a tura su a baya zuwa dakin grind don samun wani ƙarin grinding yayinda guga masu inganci za a tara su ta hanyar tarin guga na cyclone kuma a raba su daga ƙasan a matsayin kayan kammala. Bayan haka, iska zata shiga fan tare da ducts na dawo da iska a saman tarin guga na cyclone. Wannan tsarin yana amfani da rukunin rufewa da kuma aiki a ƙarƙashin matsa lamba mai kyau da mara kyau.

Saboda kayan suna da wasu abubuwan danshi, zafin da aka samar yayin grinding na iya haifar da zubar iska ko kumbura a cikin dakin grind domin adadin iska ya karu sosai. Bugu da ƙari, idan bakin shigar da haɗin gwiwa na pipelines ba mu kaɗan ba, iska daga waje na iya shiga cikin mil din da haifar da rashin daidaito na iska. Saboda haka, SBM yana shirya bututun fitar da iska a wajen fitar iska na fan domin jan iska mai yawa cikin tace mai. Bayan tsabtacewa, iska mai yawa ana fitar da ita. Wannan tsari na iya cimma dukkan daidaiton iska da kuma ingantaccen samarwa.

Grinding mil shine wani nau’in ingantaccen kayan aikin niƙa na ultra-fine, wanda Raymond mil yakamata ya zama wakili. Da zarar an kunna injin, ci gaba da ciyarwa da fitarwa zasu kasance lafiya, tare da kaurin da aka tsara ta hanyar fan da analyzer. Ba ya bukatar allo, wanda shine fa'idar da ke hana na'ura daga toshewa.

Fasahar mill na Raymond tana haɗa bushewa da nika a cikin mashin ɗin ƙafa wanda zai iya kawar da kayan bushewa masu zaman kansu wanda hakan zai rage jarin hannun jari, lokacin sarrafawa da kuma kulawa. A matsayin mafi yawan amfani da wakili da kuma kayan aiki masu muhimmanci don zurfin sarrafawa na ma'adanai marasa ƙarfe, mill na Raymond yana da ƙarfin tara kuzari da kuma kyakkyawan tasiri ga muhalli.

Babban na'urar watsawa ta karɓi akwati mai rufewa da pulley, don haka watsawar tana cikin tsari da abin dogaro.

An yi amfani da karfe mai inganci da aka shigo da shi don muhimman sassa. Ana amfani da kayan aiki masu jure gajiya masu inganci ga sassan niƙa.

Millin Raymond yana rufe karamin yanki, kuma yana iya kammala shirin foda cikin inganci da kuma ingancin samfurin ƙarshe yana daidaito kuma ƙimar tacewa na iya kaiwa 99%;

Shigar fasahar sarrafawa mai tsakiya daga ƙasashen waje a cikin tsarin wutar lantarki na iya tabbatar da aikin mara ɗan adam na dakin aiki da kuma sauƙaƙe gyaran.

Crusher din molar babban Crusher ne da aka girka kuma yana karɓar gwajin ba tare da yük ba a cikin dakin aikin masana'anta. Duk da haka an raba shi zuwa sassan don jigilar kaya.

Yi kyakkyawan aiki game da kulawar yau da kullum na Millin Raymond.

Daidaiciyar aiki na Millin Raymond yana da mahimmanci. Aiki mara kyau na iya haifar da lalacewa ga Millin Raymond da rage tsawon lokacin sabis, wanda zai iya haifar da asarar kuɗi mai yawa sakamakon tsawon lokaci na dakatarwa.

Yi kulawa da tsarin abinci na Millin Raymond.

Hanyar samar da millin Raymond yana gaba ɗaya abinci - fasa - rarraba - tarin foda. Kuma rarraba da tarin foda shine mahimmin hanya. Duk da haka, saboda ƙwanƙwasa mai ƙanƙanta da babban diamita na impeller yana sa tazarar ƙwanƙwasa ya yi fadi sosai, millin gargajiya yawanci zai bayyana ƙarancin sauri, rashin daidaiton saurin layi na ciki da waje, mara kyau ƙira mai kyau, leakages na toka, wanda ke haifar da rashin ingantin rarrabe, yawan leakages na manyan kwayoyin, da sauransu. Bugu da ƙari, tsarin tarin foda na millin gargajiya na iya haifar da yaduwar kura, wanda ke shafar ingancin aikin kuma yana haifar da ɓarna.

Millin Raymond da aka inganta an inganta shi a R&D, ƙira da aikin, musamman a muhimman sassa na Millin Raymond. An fi amfani da kayan hadakar tare da thickened processing, wanda ke tabbatar da ƙarfi mai kyau na jurewa, jurewa lalacewa da ƙarfin hali. Ba kawai yana inganta aikin samarwa da ingancin Millin Raymond ba, har ma yana rage tasirin kura da hayaniya a cikin tsarin samarwa, kuma mafi mahimmanci, yana cimma samar da muhalli mai kyau da warware matsalar gurbatar muhalli.

Yaya za a zaɓi Millin Raymond da Millin Ball?

1. Millin Raymond ya fi kyau fiye da Millin Ball a cikin hanyar yanka, injin Raymond yana kusan dacewa da duk kayan da Millin Ball yake aiki da su. Tare da ƙarin fito, ƙaramin amfani da makamashi da kyakkyawan kariya ta muhalli, ingancin samfurin ƙarshe ma ya fi na Millin Ball.

2. Tashar Raymond tana ɗaukar ƙaramin fili idan aka kwatanta da tashar ƙwallo.

Menene muhimman, amma marasa ƙarfi sassan tashar Raymond?

1. Matsa kayan amma da ruwan matsawa. Da zarar matsa kayan da ruwan matsawa na tashar sun gaji sosai, zai kawo wani tasiri ga samfuran da rashin daidaiton fadin samfuran da aka gama.

2. Tsarin shoveli. Lokacin da wukake shoveli na tashar suka gaji sosai, ba za su iya ɗaukar kayan ba, wanda hakan zai kawo babban tasiri ga aikin tashar.

Ta yaya za a magance matsalar fitar da kura a tashar Raymond?

Fitar da kura matsala ce daga mai tattara kura. Tashar Raymond na gargajiya ta kai matsayin kare muhalli mafi girma ta hanyar inganta aikin mai tattara kura.

Da fatan za a cika fom ɗin da ke ƙasa, kuma za mu iya gamsar da duk bukatunku ciki har da zaɓin kayan aiki, ƙirar shirin, tallafin fasaha, da sabis na bayan-sayarwa. Za mu tuntuɓe ku da zarar an samu damar.