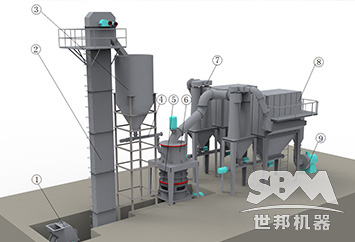

Wannan cikakken tsarin samar da ƙarfin haɗin an samar da shi ta SBM. Tare da kayan aikin, layin samarwa ya iya samun kulawa ta tsakiya, samarwa ta atomatik da warware matsaloli yayin tsarin samarwa. Bugu da ƙari, aikin ya yi fice wajen gudanarwa mai sauƙi, koyon sa da amfani, da sauransu.

Abu:Clinker siminti sulfate-aluminium, siminti Portland, Metakaolin, Lime, Gypsum, da sauransu

Girman Shiga:<1mm

Ruwan sha:<5%

Amfani:Slip-casting & kayan cike

| Albarkatun الخام | Bukatun samfuran da aka gama | Babban halaye | Lokacin saiti(minti) | Karfin matsa lamba(MPa) | Hankali Matsakaici(%) | Karfin jurewa(KN) |

|---|---|---|---|---|---|---|

| Siminti | 1250mesh D90% |

Gamshe gwada sakamakon MT219-2002 |

Farkon saiti 3~4mintuna |

0.5h >12~ 16 MPa |

0.5h≥ 0.1~0.18 | 0.5h ≥ 50~62 |

| Lime | ||||||

| Gudun saiti na karshe <7.5mintuna |

1h >18~ 24 MPa |

|||||

| Gypsum | ||||||

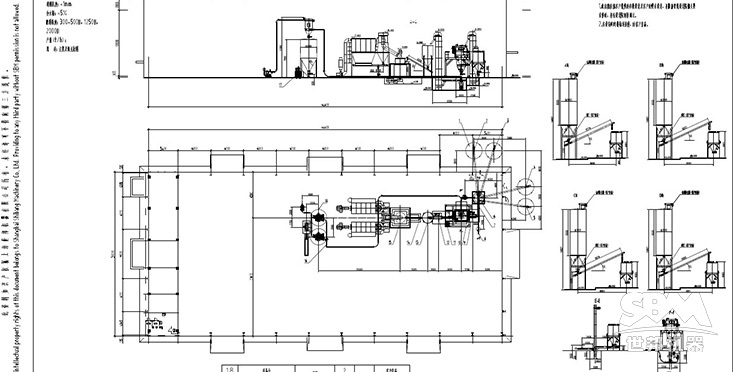

1、Ba a Nika: Bayan ƙaddamar da tsarin nauyi, ana kimanta kayan albarkatun na wakilan jurewa da dandamali; daga baya ana cika kayan zuwa tsarin juyawa mara nauyi don a juyar; a ƙarshe, ana aika su ta tsarin jigilar pneumatic zuwa tankin kayayyakin da aka gama don ajiya. Lokacin da aka shirya kayayyakin da aka gama a cikin jaka, suna iya zama an yi musu jigilar sayarwa.

2、Nikan Kayan: Ana cika kayan albarkatun zuwa tsarin nauyi ta hanyar kayan cika don a kimanta da kamfanoni, sannan ana juyawa da haɗawa a cikin tsarin juyawa mara nauyi. Bayan haka, kayan haɗin suna shiga tsarin nika don a nika su da kuma tsara su. A ƙarshe, ana aika kayan ta hanyar tsarin jigilar pneumatic zuwa tankin kayayyakin da aka gama don ajiya sannan a shirya su a cikin jaka bisa ga bukatun. Duk da haka, yana buƙatar nau'ikan fasahar sarrafawa guda biyu, hanyoyin samarwa guda biyu suna rabaiti da guda ɗaya na layin samarwa. Tare da haɗin gwiwar tsarin mai kyau, layin samarwa yana ɗaukar ƙananan wuri sosai kuma yana rage zuba jari a cikin kayan aikin sosai.

Daban da zane na tsari, wannan layin samarwa an inganta shi bisa ga bukatun abokan ciniki. Dukkan layin samarwa ya ƙunshi babban kayan aiki na SCM1250 ultrafine mill (babban kayan aiki), jigilar mai hurawa, na'urar kunshin foda, jigilar pneumatic da sauransu, wanda ya cika bukatun hanyoyin samarwa guda biyu na wakilan jurewa.

| A'a | Suna | Samfuri | Adadi |

|---|---|---|---|

| 1 | Jigilar mai hurawa | LS315 | 2 |

| 2 | Matsala | JLC | 1 |

| 3 | Jigilar mai hurawa | LSY250 | 4 |

| 4 | Hopper | 60m³ | 4 |

| 5 | tankin kayayyakin da aka gama | 2 | |

| 6 | na'urar kunshin foda | jaka kunshin | 1 |

| 7 | jigilar pneumatic | QL | 1 |

| 8 | ultrafine mill | SCM1250 | 1 |

| 9 | jigilar spiral | LS219 | 1 |

| 10 | tankin hawan ma’adinai | SCM1250-1 | 1 |

| 11 | na'urar tura kwano | TH300 | 2 |

| 12 | tsarin haɗawa kayan | WZ-6C | 1 |

| 13 | jigilar spiral | LS160 | 1 |

| A'a | Suna | Samfuri | Adadi |

|---|---|---|---|

| 1 | Motor na mill | Y355M2-6 | 1 |

| 2 | Mai rarrabawa | Y225S-4 | 1 |

| 3 | Mai tura | TH-300 | 1 |

| 4 | Motor na mai tura | Y100M-4 | 1 |

| 5 | Feeder | Carina Belt Conveyor | 1 |

| 6 | Bunker(Silo) | 10m³ | 1 |

| 7 | Discharging Spiral Conveyor | LS219 | 2 |

| 8 | Discharging Valve | ZJD-250 | 3 |

| 9 | Blower Motor | Y250M-2 | 1 |

| 10 | Hammer Crusher | PC600×800 | 1 |

| 11 | Hammer Crusher Motor | YB2-280S-6 | 1 |

| 12 | Dust Collector | LDMC250 | 1 |

| 13 | Air Compressor | LG6.2/8 | 1 |

| 14 | Ultrafine Mill | SCM1250 | 1 |

Tare da taimakon PLC da gudanarwa mai gani, matakin aikin kai tsaye yana da kyau sosai; Tare da fa’idar fasahar SBM, tsarin tsarawa yana da kyau sosai.

Tsarin ciyar da kayan aiki: Ana ciyar da siminti, lime da gipsa da aka raba da wasu kayan aiki na mai kulawa zuwa tsarin auna nauyi ta hanyar kayan aikin ciyarwa.

Tsarin auna nauyi: Dangane da kima da aka saita, ana auna nauyin kayan aiki daban-daban.

Tsarin jujjuyawa: Bayan tsarin auna nauyi, kayan suna jujjuya da hadewa a cikin mai hadawa mara nauyi.

Tsarin grinding: Ana ciyar da kayan hadakkar zuwa injin niƙa mai ƙanƙara ta hanyar ciyarwar skrwu don a niƙa da kuma rarraba. A matsayin muhimmin tsari, SCM1250 mai niƙa ƙanƙara yana niƙa foda har sai foda ya zama mai kyau kamar 1250 mesh.

Tsarin tura, ajiya da shiryawa: Ana tarawa kayayyakin da aka gama ta hanyar mai tattara kura na puls da a tura su zuwa tanki ta hanyar tsarin isarwa na pneumatic, a shirya ta hanyar tsarin shiryawa da kuma kaiwa.

SBM ta bayar da shirin aikin ƙwararru, ciki har da shirin wurin aiki, mafi kyawun tsarin injin da kasafin kudin da sauransu. Menene mafi mahimmanci, SBM na karɓar bukatun da aka tsara a cikin aikin tsarawa.

Gaba ɗaya layin samarwa ya fahimci kulawa mai ma'ana ta PLC, yana cika bukatun abokin ciniki, kamar ingantaccen aiki, ƙananan gurbacewar yanayi da ƙaramin kaurin aiki.

SBM tana da ƙungiyar injiniyoyi masu shigarwa na ƙwararru wanda ba wai kawai zai taimaka wa abokan ciniki kammala aikin shigarwa bisa ga bukatunsu cikin gajeren lokaci ba, har ma yana ba da hannu wajen horar da masu aiki.

Bayan shigarwa da kulawa, Sashen Tsaro na Abokan ciniki na SBM zai kula da ayyukan bin diddigin, ciki har da bayar da sassa na ajiya, gyara da inganta, da kuma ziyartar wurin aiki, da sauransu.

Babban kayan aiki a cikin samar da mai kulawa shine SCM1250 Ultrafine Mill ---- injin mai inganci amma mai arha wanda aka kirkiro ta hanyar haɗawa da kwarewar samar da niƙa da fa'idodin ƙirƙirar niƙa a cikin gida da kasashen waje.

Sabon tsarin niƙa daga teburin niƙa, gabar niƙa da gagarin niƙa na iya inganta ingancin niƙa. A matsayin yanayi na irin girman da iko guda, ikon wannan niƙa yana da 40% mafi girma fiye da na niƙar zafi & mai juya da kuma fiye da sau biyu na niƙa kwano; yayin da kuma amfanin tsarin shine kawai 30% na niƙar zafi.

Dukkan mai raba foda na kai ɗaya da mai raba foda na kai da yawa suna zaɓi. Saboda gudun kowanne rotor na mai raba foda na kai da yawa yana iya zama da aka daidaita, ana iya tara kayayyakin da aka gama kai tsaye, ba tare da ƙarin winnowing ba, kuma babu kayan da ba su da kyau. Daga cikin kayayyakin ƙarshe, foda mai ƙanƙanta fiye da 2μm yana iya kaiwa 70%.

Amfani da mai tattara kura na pulse, mai shayar da sauti da dakin da ba ya jawo sauti na iya cire kura da rage hayaniya, wanda ke daidai da ka'idojin ƙasa.

Mayafin gasa da zobe an yi su da kayan musamman. Saboda haka, rayuwar sabis tana tsawon 2-3 sau fiye da na mai karya tasiri da mai karya turbo a cikin yanayi iri ɗaya. Hakanan ana iya amfani da su na tsawon shekaru 2-5 lokacin da aka yi amfani da su don gasa calcium carbonate da calcite.

“Bayan ziyara da gwaji na shafin, injiniyoyi daga SBM sun ba mu wani kyakkyawan zane. A karshe, mun yarda da zane nasu, muna amfani da SCM1250 a matsayin babban kayan aiki. Yanzu kayan aikin suna gudana da kyau, kuma babban ƙarfin, inganci da dindindin suna daidai da abin da muke bukata. Kayayyakin SBM sun cancanci kyakkyawar suna da suke da shi.”

A matsayin sabon nau'in hanyar tallafi na ma'adinai na kwal, haɗa dutse yana amfani sosai a cikin samar da ma'adinai a cikin manyan ma'adinai. Kwatancen aikace-aikacen tsarin haɗa dutse yana kaiwa har zuwa 85% kuma yana nuna ƙarfin zama da fa'idodi, ya zama babban jabun a cikin fasahar tallafin hanyoyi. A matsayin babban sashi na haɗa dutse, bukatar manhajar tsatira na karuwa cikin sauri, musamman manhajar tsatira ta Cement da manhajar tsatira ta Resin.

A zahiri, manhajar tsatira ta Cement wani nau'in siminti mai sauri ne. Akwai hanyoyi guda biyu don ƙirƙirar sa, ɗaya ana yin sa ne ta hanyar haɗa siminti na Portland mai kyau tare da ƙananan kaso na kayan sauri, kayan ƙarfi na farko da kayan faɗa; wani kuma shine haɗa dukkan kayan farko, ƙona su, sannan a sassaka su zuwa ɗan ƙaramin ƙura a ƙarshe. Alamomin inganci ya kamata su bi MT210-2002.

Manhajar Tsatira ta Resin wani nau'in kayan gini ne na tubulu, wanda aka samar ta hanyar resin polyester wanda ba a cika ba na manhajar kapsule da ƙura ta marble, kayan gaggawa da haɗawa

Manhajar tsatira yawanci ana amfani da ita a matsayin kayan haɗa dutse a cikin ma'adinai na kwal, hanyoyin kwal, tunkulus, ma'adinai na culvert, ganuwar rubble da sauran gine-ginen ƙasa.