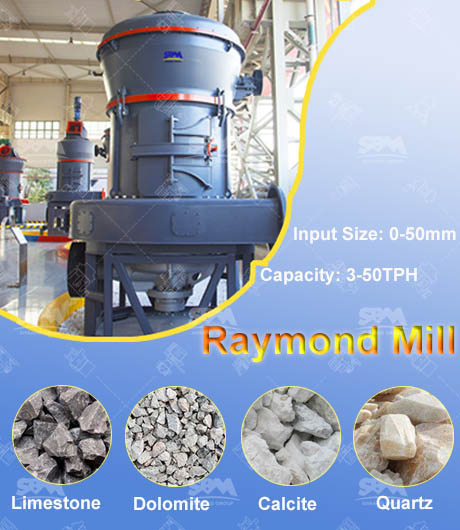

The Raymond Mill is a grinding machine, suitable for the preparation of various kinds of mineral powder and coal powder preparation.

Materials: Barite, calcite, potash feldspar, talc, marble,

limestone, dolomite, fluorspar, lime, activated clay, activated carbon, bentonite,

kaolin, cement, phosphate rock, gypsum, etc.

Applications: Metallurgy, chemical engineering, building materials,

mining, pharmacy, cosmetics and other fields

➤Moh's hardness below Grade 7

➤Moisture below 8%

➤Non-combustible and non-explosive

➤Feed size ranging from 40 to 400meshes

In 1906, C.V. Grueber founded a machinery factory in the southern suburbs of Berlin. Using his patents obtained in the United States, he produced the first Maxecon mill and used it as the coal grinding equipment for the MOABIT power station. The grinding power can reach 5TPH. In the past few years, nearly 600 units have been sold and used in different industries. In the same period, BEWAG planned to develop a coal mill with a higher output. After E.C. Loesche took over and headed the C.V. Grueber Machinery Plant, he decided to purchase the patented Raymond Centrifugal Ring-roller Mill from the United States to produce the first generation of Raymond Mill system.

However, practices proved that the fineness of finished products produced by Raymond Mills was dissatisfactory. Usually, the fineness was about 400 meshes, with very little material’s fineness up to 1000 meshes, which did not meet the requirements of refined development. This kind of Raymond mill was only suitable coal materials with soft, low ash and good grinding property, because the grinding force (centrifugal force) of Raymond coal grinding mill was limited by the diameter and rotation speed of grinding roller at that time. However, German coal was characteristic of hard and high ash content, which required higher grinding power. Therefore, Raymond mill of this structure wasn’t prevalent in Germany as itwas difficult to meet the grinding requirements. But it was surprising that this kind of Raymond mill was just suitable for the coal quality in the United States, there was no doubt that Raymond mill was widely promoted and applied in the United States.

In 1925,E.C.Loesche summarized the use characteristics and disadvantages of the first generation of Raymond coal mill and decided to further improve the structure of Raymond mill. He developed a mill whose grinding principle is opposite to the first one, which was called improved Raymond mill.

The ventilation of this improved Raymond mill system has two modes: positive pressure and negative pressure direct blowing. The patent of this type of Raymond mill was soon acquired by Combustion Engineering (a company in America).

The Raymond mill upgraded were still problems on its roller so far. Although the roller diameter increased slightly, it didn’t work very well.

Later, Combustion Engineering developed a new generation of Raymond mill on the ground, which named VR mill.

The structure of this Raymond mill was similar in many aspects to that of the current Loesche mill. However, it was different from Loesche mill on its cylindrical grinding roller and grinder table with a 15 degree sloping surface. The grinding roller was equipped with a roll-out device for inspection and maintenance. And it also equipped a protective device to prevent metal contact between the grinding roller and the grinding table. In addition, the grinding roller can be lifted in advance before the mill starts that can reduce the pull-in torque.

Raymond mills were usually used to make pulverized coal in the United States. The fineness of finished product varies between 250-325 mesh (fineness and output can be adjusted during operation).

Since Raymond Mill was patented, it has been more than fifty years. With years of development and improvement, more and more types and models of Raymond mill are developed with stable performance, strong adaptability and cost-effective performance.

SBM has launched three upgrade series of Raymond Mills, MB5X Pendulum Roller Mill, MTW European Grinding Mill and MTM Medium-speed Grinding Mill respectively. Compared with the first generation of Raymond Mills, these three types of grinding mills are more energy-efficient and environmentally friendly, have more sophisticated automatic control systems, and can help users to move toward refined and large-scale development.

According to accumulation and experimental analyses of on-site test data for more than thirty years, SBM, a Chinese grinding mill manufacturer, has researched and developed the fifth-generation pendulous hanging grinding mill – MB5X grinding mill. All non-combustible and non-explosive brittle mineral products whose Moh's hardness are below Grade 7 and water content below 6% could be ground by this grinding mill.

MTW European Grinding Mill is innovatively designed through deep research on grinding mills and development experience. It absorbs the latest European powder grinding technology and concept, and combines the suggestions of 9158 customers on grinding mills. This grinding mill perfectly satisfies the production demands of the customers on 200-33μm (80-425Mesh) fine powder.

As we all know, Raymond mill is mostly used for processing non-metal ores(coal is included) and many manufactured products contain a certain amount of free moisture. Nowadays, titles like "can raymond mill process kaolin" and "can raymond mill process celatom " are popping up all over the internet. Raymond mill is gradually widely used in different fields.

In paper making industry, celatom is,after processing by Raymond mill,usually used as filler when making cigarette paper, filter paper, deodorant paper, packaging paper, decorative paper, which can reduce the raw material and increase the characteristics of paper.

In metallurgy industry, Raymond mill can be seen in the field such as powder metallurgy, mechanical alloying, metallurgical raw material processing, metallurgical waste slag utilization, foundry type sand and stone, super hard material and solid lubricant, etc.

In the building materials industry, the important parts of Raymond mill are made of high quality steel, and the wear-resistant parts are made of high performance wear-resistant materials, which ensure the reliable operation in construction waste recycle.

In the chemical industry, Raymond mill is used to process gypsum powder, talcum powder, titanium dioxide, bone powder, shell powder, carbon black powder, coal powder, various kinds of rubber powder, alum and other chemical powders.

In addition, Raymond mill is applicable for small and medium-sized plant. Raymond mill is most effective processing materials that are 5 or less on the Mohs scale of hardness. There are a few limitations, but the most practical are soft to medium hard materials.

Raymond mill is composed of important devices such as grinding device, classifier, reducer, star rack and grinding roller assembly and other wear-resistant parts.

The grinding device: a device equipped with professional grinding rollers and grinding rings. The grinding process is mainly completed in the grinding device; the crushed fine powder is going with the grading airflow and reasonably graded by the classifier.

The reducer: a power transmission mechanism that uses the speed converter of gears to decelerate the rotary number of the motor and thus get a larger torque.

The star rack: when the mill is running, the device is driven by the main shaft and then realizes the rotation of the grinding roller and the grinding ring.

The grinding roller assembly: a set of device which hang on the star rack, also the core device of Raymond machine and the part that is most prone to failure and needs attention to timely refueling.

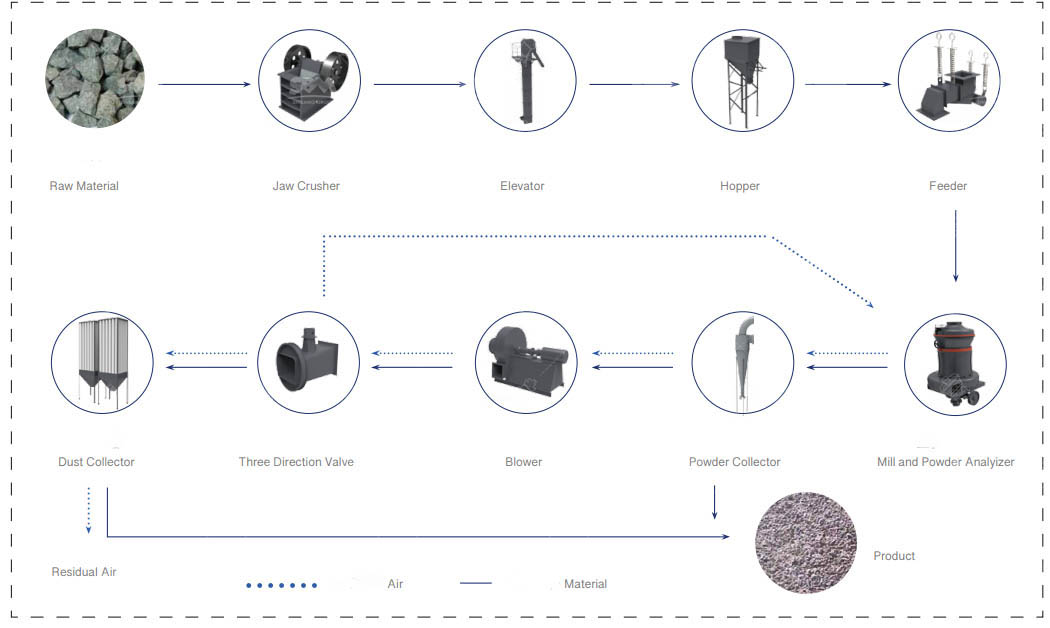

After jaw crushers break large bulky materials to smaller ones, elevators work to send materials to the hopper. Then, by electromagnetic vibrating feeders, broken materials are evenly and quantitatively sent to the grinding chamber of Raymond Mill.

After grinding, materials are blown away by airflow to the powder concentrator for classifying. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. And, after that, the airflow would go into the fan along with the air return duct at the top of cyclone power collector. This system adopts a closed circuit and runs under positive and negative pressure.

Because materials have a certain content of moisture, heat generated during grinding may lead air evaporation or swell in the grinding chamber so that the amount of airflow increases sharply. Besides, if the feed port and joints of pipelines are not sealed well, external air may intrude the grinding mill and lead imbalance of airflow. So, SBM arranges exhaust valves at the air outlet of the fan to induce redundant air into the bag filter. After purifying, the redundant air is discharged. This arrangement can achieve both the balance of airflow and the eco-friendly production.

Grinding mill is a kind of high-efficiency ultra-fine grinding equipment, among which Raymond mill should be the representative. Once the machine is started, continuous feeding and discharging will be worry-free, fineness being controlled by fan and analyzer. It does not need screen, which is the advantage that perfectly prevents equipment from clogging.

Raymond mill's technique combines drying and pulverizing in the roller mill which may eliminate independent drying equipment thus reducing capital investment, processing time and handling. As the most widely used representative and important equipment for deep processing of non-metallic minerals, Raymond mill is especially energy-saving and environmental friendly.

The main transmission device adopts sealed gear box and pulley, so the transmission is stable and reliable.

Imported high-quality steel is used for important parts. High-performance wear-resistant materials are used for the grinding parts.

A Raymond Mill covers a small area, and can complete powder preparation efficiently and the fineness of the finished product is uniform and the screening rate can be as high as 99%;

The introduction of foreign centralized control technology in the electrical system can realize the unmanned operation of the workshop and make the maintenance simple and convenient.

The jaw crusher is a large crusher installed and receives no-load testing in the manufacturer's workshop. However it is disassembled into components for transport.

Do a good job about daily maintenance of the Raymond Mill.

Correct operation of the Raymond Mill is a must. Improper operation may cause damage to the Raymond Mill and shorten its service life, which may cause considerable economic losses due to long-term shutdown.

Control the feed standard of the Raymond Mill.

The production link of Raymond mill is generally feeding - crushing - grading - powder collection. And that the grading and powder collection is the core link. However, because that the narrow blade and huge impeller diameter makes the blade gap too wide, the traditional mill will generally appear low speed, uneven internal and external linear speed, bad seal design, leakage of ash, resulting in poor grading efficiency, more leakage of large particles, etc. Moreover, the traditional Raymond mill powder collection system can easily cause dust spillage, which affects the quality of the process and causes waste.

The improved Raymond mill is upgraded in R&D, design and workmanship, especially in the important components of the Raymond mill. More composite materials are used with thickened processing, ensuring stronger pressure resistance, corrosion resistance and toughness. It not only improves the production performance and quality of Raymond mill, but also reduces the impact of dust and noise in the production process, and more importantly, achieves environmentally friendly production and solve the problem of environmental pollution.

How to choose Raymond mill and ball mill?

1. Raymond mill is better than ball mill in its grinding range, Raymond machine is almost applicable for all the material that ball mill is for. With higher output, lower energy consumption and better environmental protection, its finished product fineness is also better than ball mill.

2. Raymond mill occupies smaller area compared with ball mill.

What are the important but vulnerable parts of Raymond mill?

1. Grinding rollers and grinding rings. Once the grinding rollers and grinding rings of the mill are seriously worn out, it will bring certain influence to the products and the uneven fineness of the finished products.

2. Shovel structure. When the shovel knife of the mill is seriously worn, it will not be able to shovel up the material, resulting in a great impact on the efficiency of the mill.

How to solve the problem of dust emission in Raymond mill?

Dust emission is the problem from dust collector. The traditional Raymond mill has reached higher environmental protection standard by improving the performance of dust collector.

Please fill out the form below, and we can satisfy any of your needs including equipment selection, scheme design, technical support, and after-sales service. We will contact you as soon as possible.