SMP Modular Mode

Standardized, quick installation, short cycle time, one-stop service

Learn More >Site Visit / High Market Share / Local Branch / Spare-parts Warehouse

The MTM Medium-speed Mill has been enhanced with optimized inner structure and key components. For instance, the new supercharging device significantly boosts production capacity, lowers spare parts costs, and minimizes downtime. As per customer testimonials, the MTM series grinding mills excel in producing 60-325 mesh sized powders.

MTM features an integrated system, requiring minimal investment in construction and foundation for transforming bulk materials into finished powder.

MTM has an energy consumption of more than 60% lower than that of the same grade of ball mill under ideal working conditions.

MTM trapezium grinding mill adopts high efficiency impeller fan, which improves the efficiency of air induction from 62% to 85%.

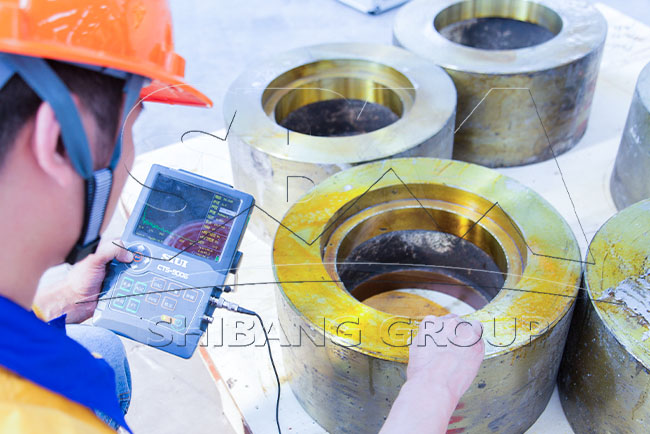

SBM can offer customers technical services about products and original spare parts to ensure the worry-free operation.

Optimize production efficiency through our digital solution, a saas platform

Learn More >

Please fill out the form below, and we can satisfy any of your needs including equipment selection, scheme design, technical support, and after-sales service. We will contact you as soon as possible.