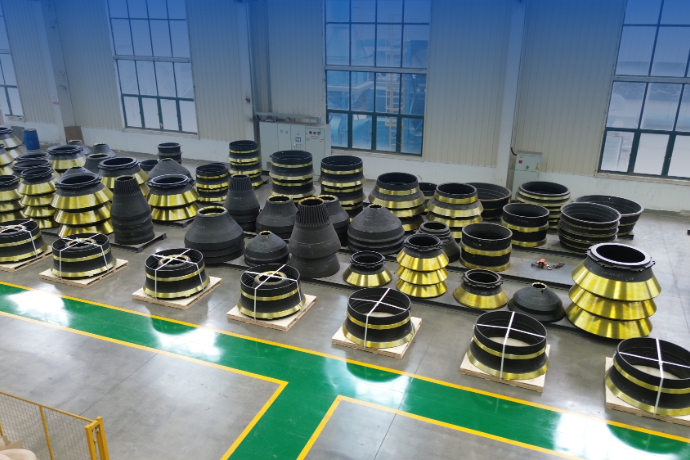

This customer is a renowned enterprise in the Malaysian construction industry. Upon receiving a recommendation from a friend, the customer reached out to SBM's Malaysia branch. After gaining a comprehensive understanding of the customer's specific requirements, including project duration, budget, applications of finished aggregates, and work site conditions, SBM customized a portable crushing plant for the customer. The customer conducted on-site inspections of several SBM projects in Malaysia and even organized an inspection team to visit SBM's Shanghai headquarters to further explore the projects, finalize the process plan, and select the appropriate equipment.