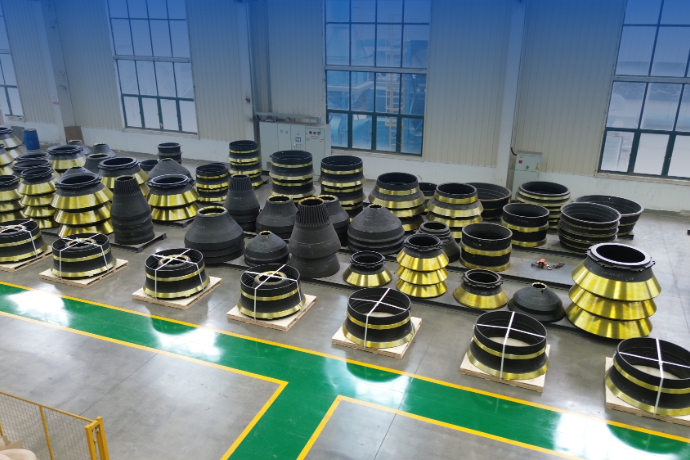

After comprehensively considering the strength and equipment, the company, together with municipal party committee and government, chose to cooperate with SBM to build a construction solid waste treatment project to ease the pressure of construction wastes.