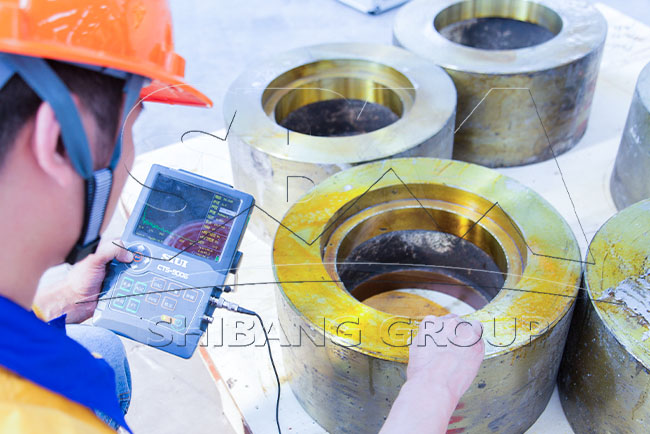

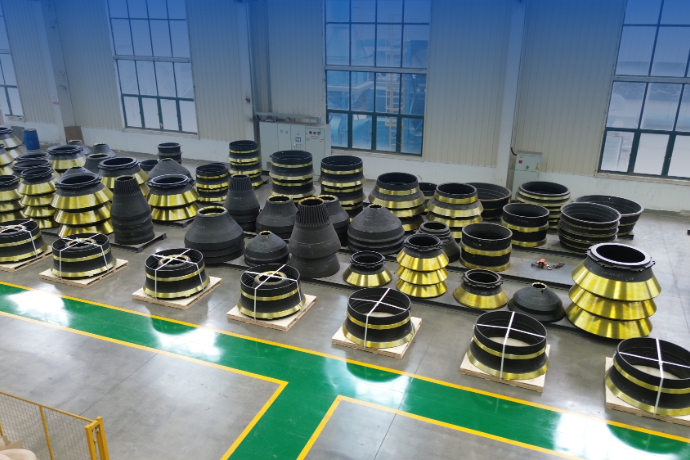

The customer, a state-owned enterprise, has stringent requirements for equipment quality and finished product standards. After conducting multiple investigations, they chose to partner with SBM. The customer is highly satisfied with the project's construction and production efficiency.