Since this limestone plant was put into production, it has been high-yield and stable for long time, and has been well received. Many customers from surrounding counties and cities have visited it.

PEW Jaw Crusher is a new crushing machine developed by SBM, the jaw crusher manufacturer, after the release of traditional jaw crusher. This jaw crusher is a perfect combination of modern science and technology and the production practice, which can better satisfy the automatic production demands of vast customers.

SBM has professional team and 30 oversea offices in the world, thus, we can dispatch engineers to visit your work site and help you customize suitable solution.

SBM provide our customers complete installation guide, commissioning services, operators training service.

SBM would like to extend our new technologies to customers by offering upgrades to their existing equipment.

The EPCO stands for "Engineering, Procurement, Construction, and Operation." With this service, you will gain cost-saving, time-saving, better-performance and higher profit.

Learn More >

On the basis of big data, AI and IoT, SBM has launched a comprehensive SAAS intelligent service platform, dedicated to providing smart IoT digital solutions for the aggregates and mining industry.

Learn More >

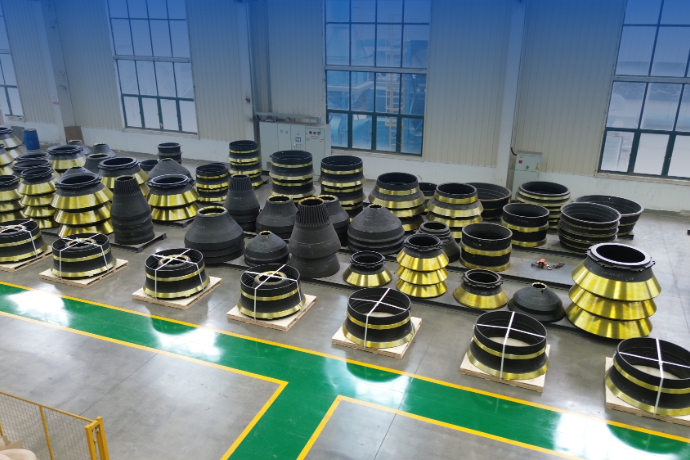

SBM has our own casting factory, as a result, we can provide cusntomers all spare parts quickly.

Learn More >Please fill out the form below, and we can satisfy any of your needs including equipment selection, scheme design, technical support, and after-sales service. We will contact you as soon as possible.