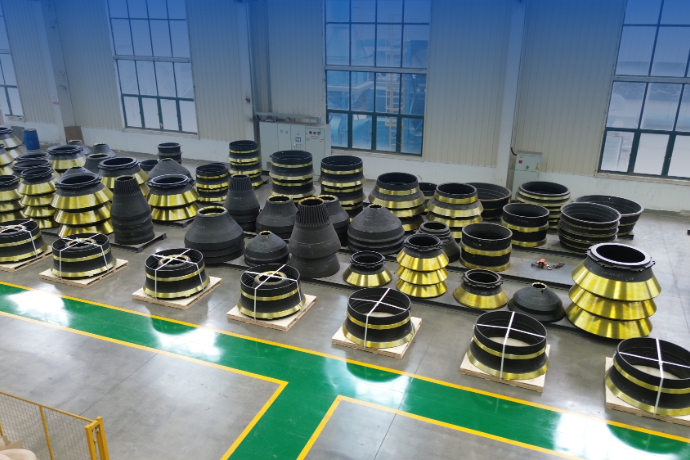

The client is the largest local real estate development company, which needs a large amount of sand aggregates every year. As the price of aggregates rises rapidly, the cost of raw materials for customers rises sharply. In order to meet their needs for aggregates, they decided to use their own granite resource to build a sand making plant. Currently, the production plant is running normally, not only meeting the customer's needs, but becoming a local landmark project.